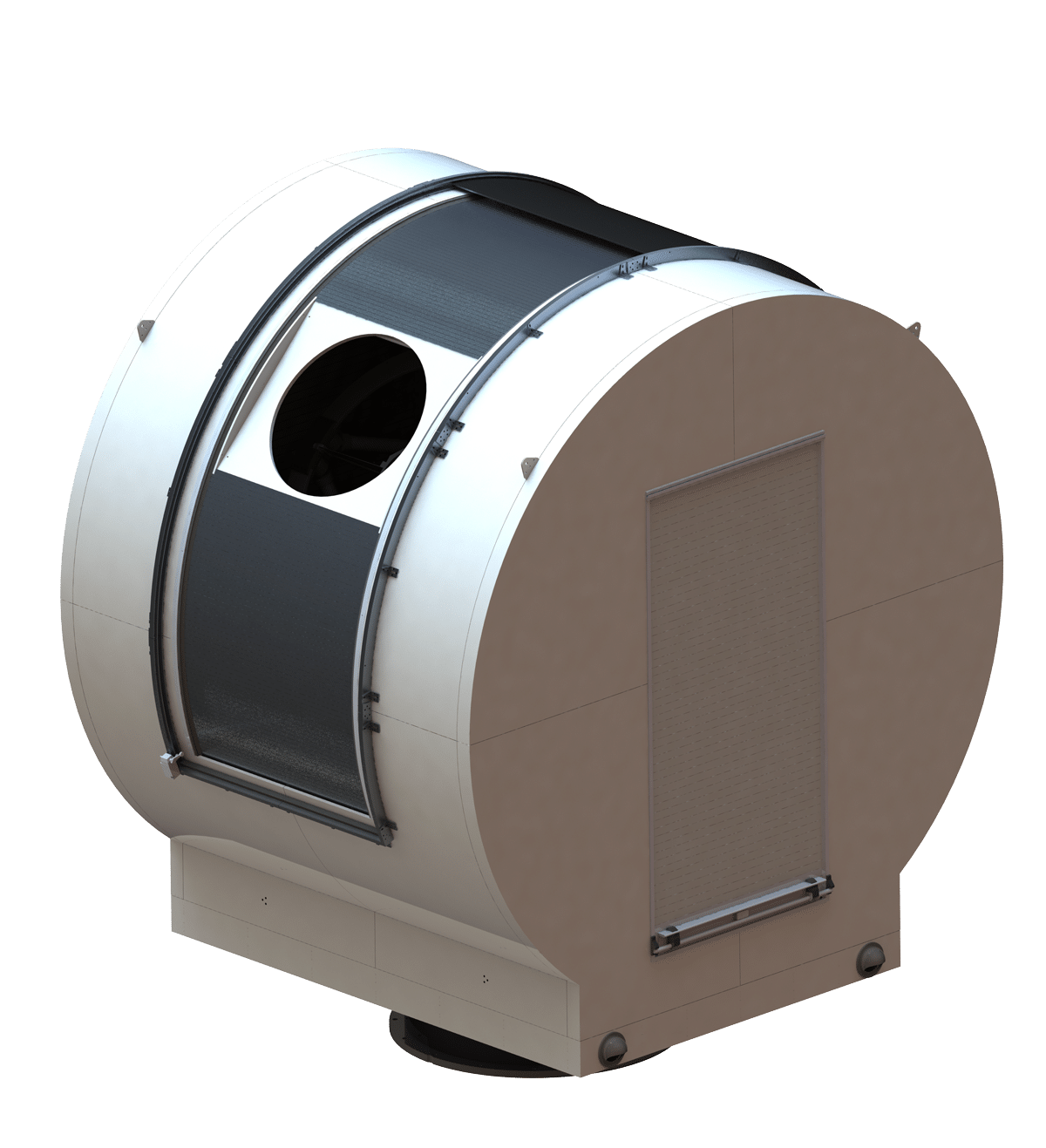

PWI Enclosures

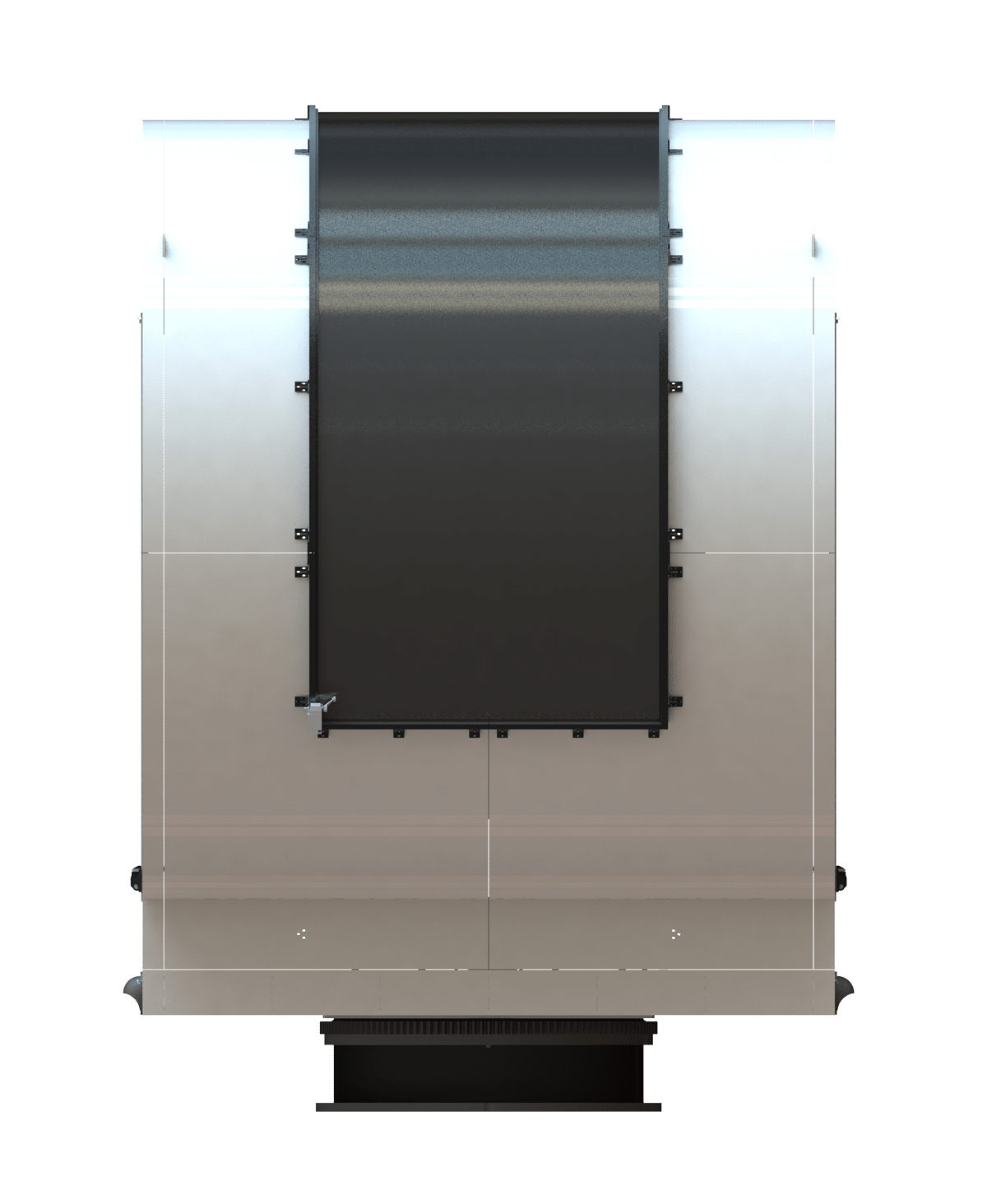

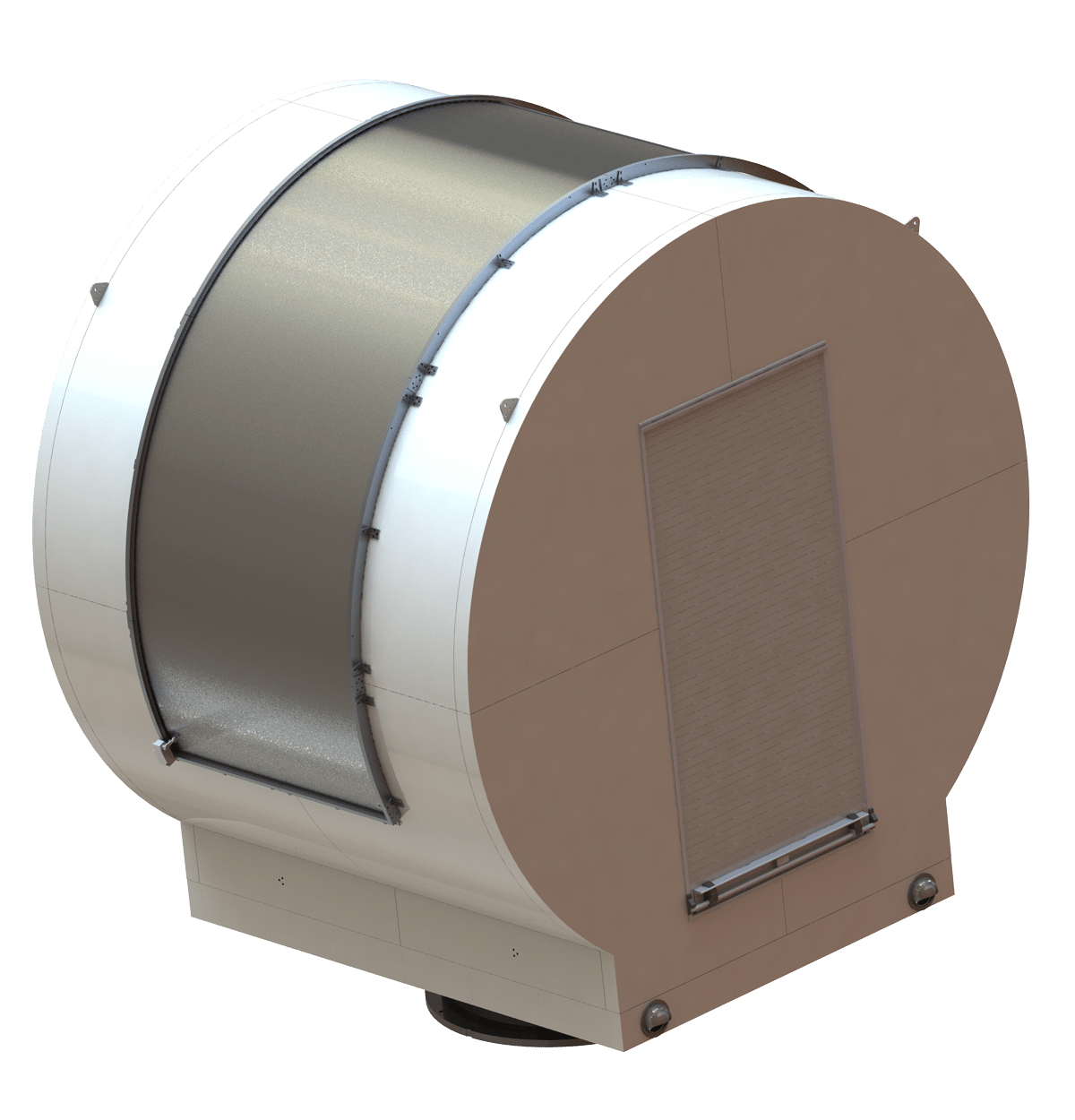

FOR L-Series mOUNTS, T600, CDK/RC700, and CDK/RC1000

inspiration

Having grown from the astronomical research market, PlaneWave Instruments has developed a long and broad understanding of historical and current approaches to observatory and telescope enclosures across our 16-year history. In our pursuit of the perfect telescope, it has been increasingly apparent that many of today’s advanced applications for our telescope and gimbal products are not ideally supported by existing enclosure systems.

Features & Details

Specifications

Power Slip Ring

AC power compatibility: 200-240 vac – 50/60 Hz. 350 megabit/second Poe. Minimum power for enclosure: 15A at 240V.

Exhaust Fans

Designed to help regulate temperature while the enclosure is open and draw air circulation through the slit to improve local atmospheric seeing when in operation.

Wind- and Weather-Resilient

Designed to withstand 120 mph wind gusts and up to -30°C temperatures.

Interiors are insulated to protect from condensation and thermal effects while exteriors are impervious to rain, snow, fog, ice, and debris.

50°/s Azimuth & 25°/s Elevation Slew Speed

Both Azimuth and Robotic Window Frame axes keep up with high-velocity subjects.

Rapid Assembly

From crate to commission in one day (with PlaneWave installation).

Reasonable Crate Sizing for Delivery

Enclosure can be shipped in two crates (one for the base and floor pieces, and one for the main shell) or within one 20-foot shipping container.

Optional Features

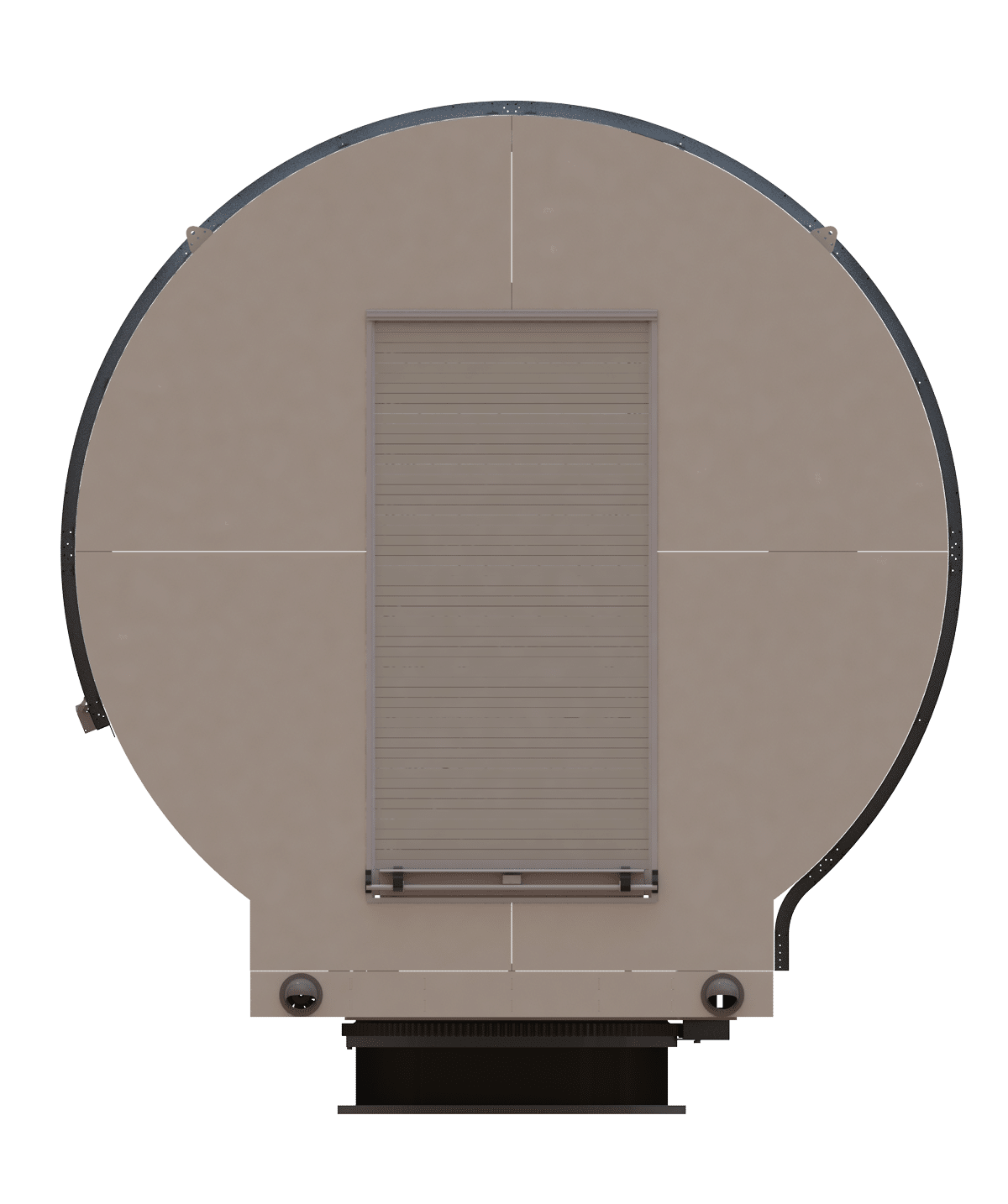

Robotic Window Frame

Optional robotic optical window frame and associated rolling seals allow even greater environmental ruggedization by minimizing wind buffeting and solar loading.

Optical Window

For the highest degree of environmental resiliency, optically polished windows can be added to seal the enclosure. With an optical window in place, your system will be protected from wind, as well as wind-driven rain, dust, pollen, and other debris. Various substrates, surface qualities, and coatings are available, including energy-rejection filtration. *Windows are available for quote

Dehumidifier

Reduces humidity levels, safeguarding your equipment and valuables from the damaging effects of excess moisture.

Uninterruptible Power Supply

Designed specifically for the outer shutter system, this feature ensures that the shutters remain fully operational, consistently providing seamless and reliable protection.

HVAC

Offered to help maintain the temperature of the enclosure’s interior and instrumentation, HVAC helps combat the effects of the external environment, ensuring it is ready to operate the moment it opens.

Configurations

Single Aperture Enclosure

- RC/CDK700

- RC/CDK1000

Robotic Window Frame with Bellows

- RC/CDK700

- RC/CDK1000

BENEFITS

Rotation of Full Structure on Industrial Sealed Bearing

- Greatly improves structural rigidity, allowing for higher rotation velocities.

- Simplifies and bolsters approaches to environmental sealing.

- Allows form factors that reduce footprint, while compatible with telescope/instrument pier-isolation from enclosure and enclosure support structure.

- Availability of high-reliability, industrial COTS bearings, and servo motors benefit MTBR.

Tighter Fit to Enclosed Instrumentation

- Eliminates human occupancy, potentially reducing permitting requirements.

- Reduces interior air volume, benefiting requirements for internal temperature and humidity regulation.

- Allows the use of smaller optical windows.

- Improves clearance requirements and mobility for trailer-mounted systems.

Superior Environmental Resiliency

- When fully assembled, only the dome slot and interior diameter of the bearing allow water, dust, and other debris entry. Placement of the rotation interface below/within drip-line protection adds further rain/snow protection.

- Optional robotic optical window frame and associated membrane seals allow even greater environmental ruggedization and potential energy-rejection filtration.

- Form factor offers obvious and significant protection from solar thermal-loading of enclosed instrumentation, improving in-dome seeing and reducing differential temperature across instrumentation for both daytime and early-night operations.

- With the enclosure, telescopes can operate in higher winds without degraded performance.