RC700 Ritchey-Chrétien Telescope

$275,000.00

The RC700 Telescope from PlaneWave Instruments is engineered for elite astronomers and astrophotographers who demand precision and scalability in their astronomical endeavors. This powerhouse system is equipped with the RC700 Ritchey-Chrétien optical tube and a high-performance direct-drive mount, making it an exceptional choice for advanced research, deep-sky imaging, and educational purposes.

The RC700 Telescope is also available in the f/12 Horizon model, designed with a fixed primary mirror capable of pointing to the horizon and even below.

Key Features of the RC700 Telescope

RC700 Optical Tube Assembly

- Aperture and Focal Length: Boasts a 0.7-meter aperture and an 8410 mm focal length at an f/12 ratio, ideal for high-resolution imaging and detailed observational studies.

- Ritchey-Chrétien Optical Design: Features a classic RC design optimized for minimal central obstruction, enhancing image contrast and reducing diffraction spikes for clearer and more detailed celestial images.

- Dual Nasmyth Focus Capability: Supports heavy instrumentation with over 300 lbs capacity on each focus port, facilitated by a controllable tertiary mirror that allows quick switching between instruments or cameras.

High-Performance Mounting System

- Direct Drive Motors: Incorporates cutting-edge direct-drive motors that ensure smooth, fast, and quiet slewing at up to 50 degrees per second, offering zero backlash and zero periodic error, ideal for precise tracking and fast repositioning.

- High-Resolution Encoders: Features on-axis 26-bit absolute encoders on each axis for ultra-precise pointing and tracking capabilities, essential for stable low Earth orbit satellite tracking.

- Advanced Tertiary Mirror System: Includes a software-controllable rotating tertiary mirror which simplifies the use of multiple instruments and switching between different observational setups without rebalancing or refocusing.

Application-Specific Advantages

Astrophotography

The RC700 excels in delivering exceptional image quality with its large aperture and long focal length, combined with a high-precision drive system. It's perfectly suited for capturing detailed images of distant galaxies, nebulae, planets, and other deep-sky objects.

Astronomy Research

This observatory-class system is a valuable asset for universities, research institutes, and commercial observatories focused on detailed celestial measurements and long-term space studies. Its robust design and advanced optical capabilities enable precise photometry, spectroscopy, and high-resolution imaging.

Free-Space Optical Communication (FSOC)

The RC700's large aperture and refractive-optics-free design make it exceptionally well-suited for Free-Space Optical Communication. These features allow for high-resolution, long-distance optical data transmission, which is critical in modern telecommunications. Additionally, the telescope's exceptional tracking capabilities ensure precise alignment with communication satellites and other terrestrial communication points, enhancing signal fidelity and system reliability in FSOC applications.

Specifications

RC700 Ritchey-Chrétien Telescope

| Aperture | 700 mm (27.56 in.) |

| Focal Length | 8,410 mm |

| Focal Ratio | f/12 |

| Central Obstruction | < 30 % of the Primary Mirror |

| Back Focus | 12.62 in (320.6mm) |

| Weight | 2,500 lbs (1134 kg) |

| Fork Assembly | Space frame steel truss |

| Fork Base | Welded stainless steel torsion box |

| Optical Tube | Dual truss structure with Nasmyth focus |

| Instrument Payload |

| Motor – Azimuth and Altitude | Direct drive 3 phase axial-flux torque motor |

| Encoder – Azimuth and Altitude | 255 mm stainless steel encoder ring with read-head yields 67.1 million counts per revolution of the telescope. This translates to about 0.019 arc-second resolution. |

| Motor Torque | Approximately 170 ft-lbs continuous (Azimuth motor) |

| Drive Electronics | Elmo Motion Control Systems drives |

| Telescope Control Software | PlaneWave Interface 4 (PWI4) Software. Incorporates PointXP mount modeling software and All Sky PlateSolve, both by Dave Rowe. Also includes automatic focusing, dew heater control, primary mirror cover control, dome control and provides HTTP and ASCOM control interfaces. Linux and Windows compatible. Native ASCOM camera drivers or Maxim DL can be used for camera control when building a pointing model within our PWI4 software. |

| Pointing Accuracy | 10 arcsecond RMS with PointXP Model |

| Pointing Precision | 2 arcseconds at sidereal velocity |

| Tracking Accuracy | < 0.2 arcseconds over a 10-second period at sidereal velocity |

| System Natural Frequency | 16 Hz or greater |

| Included Items | Heating Elements for Dew Prevention - Heating elements for dew prevention on the primary and secondary mirror. |

| Flash drive - Contains software and instructions for collimation and spacing the primary to secondary mirror. | |

| Mirror Covers- To protect the primary mirror and inside of the optical tube | |

Recommended Products

| Image | Name | Summary | Price | Buy |

|---|---|---|---|---|

| Series-5 Controller | We have designed a new 5-wire bus communication box that controls the Series-5 Focuser and Rotator, which includes M12 circular 5-wire threaded connector heads for environmental sealing.

| $800.00 | ||

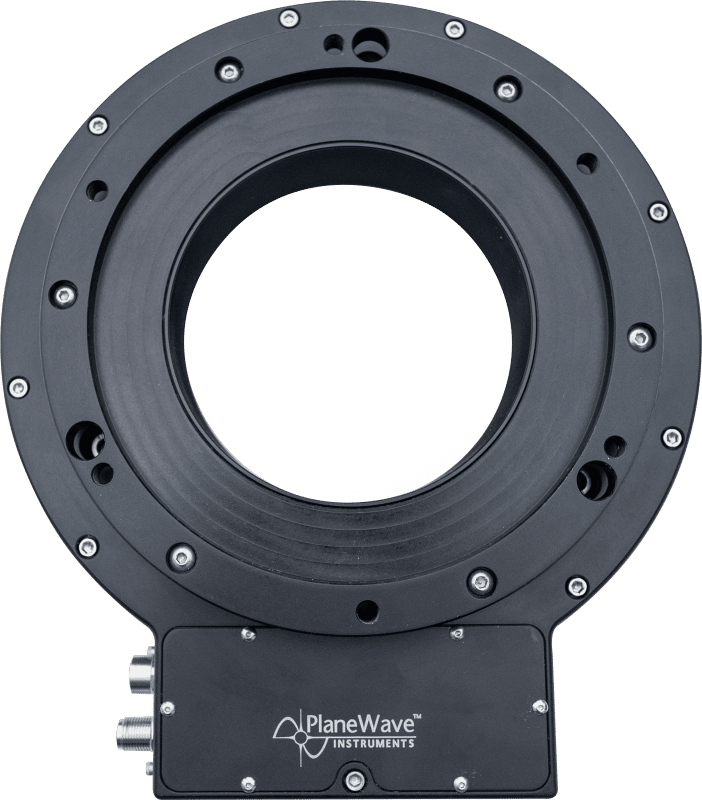

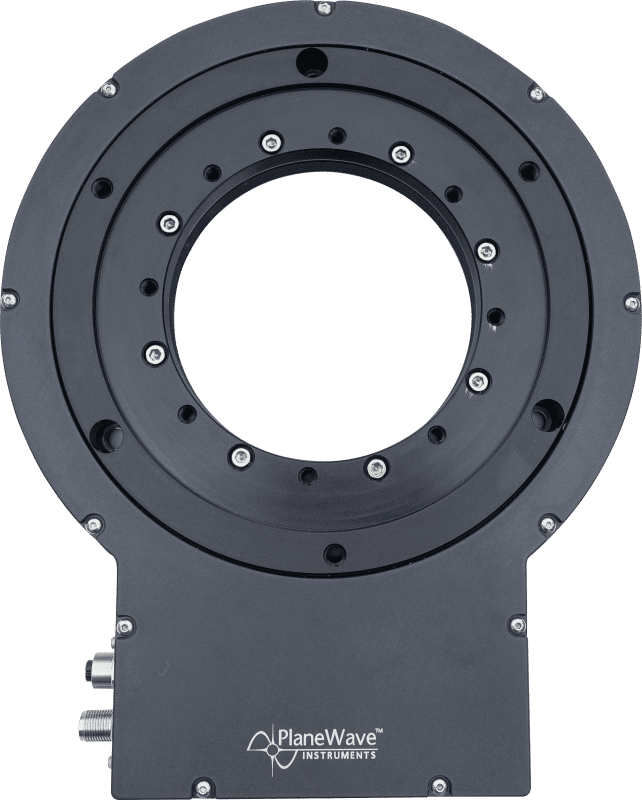

| Series-5 Focuser (Stackable with Series-5 Rotator) |

| $3,000.00 | ||

| Series-5 Rotator (Stackable with Series-5 Focuser) |

| $3,000.00 | ||

| IRF90 – Integrated Rotating Focuser |

| $5,980.00 | ||

| RC700 Upper Truss Hard Shroud | The PlaneWave RC700 Hard Shrouds are crafted to enhance your viewing experience by blocking stray light and reducing dust accumulation on the primary mirror. This set includes two carbon fiber upper hard shrouds and retaining clips for secure attachment, ensuring optimal telescope performance and mirror protection. Specifically crafted to fit between the front ring and mid-ring of the telescope, these shrouds provide enhanced functionality while safeguarding your optics for optimal viewing experiences. | $5,750.00 |