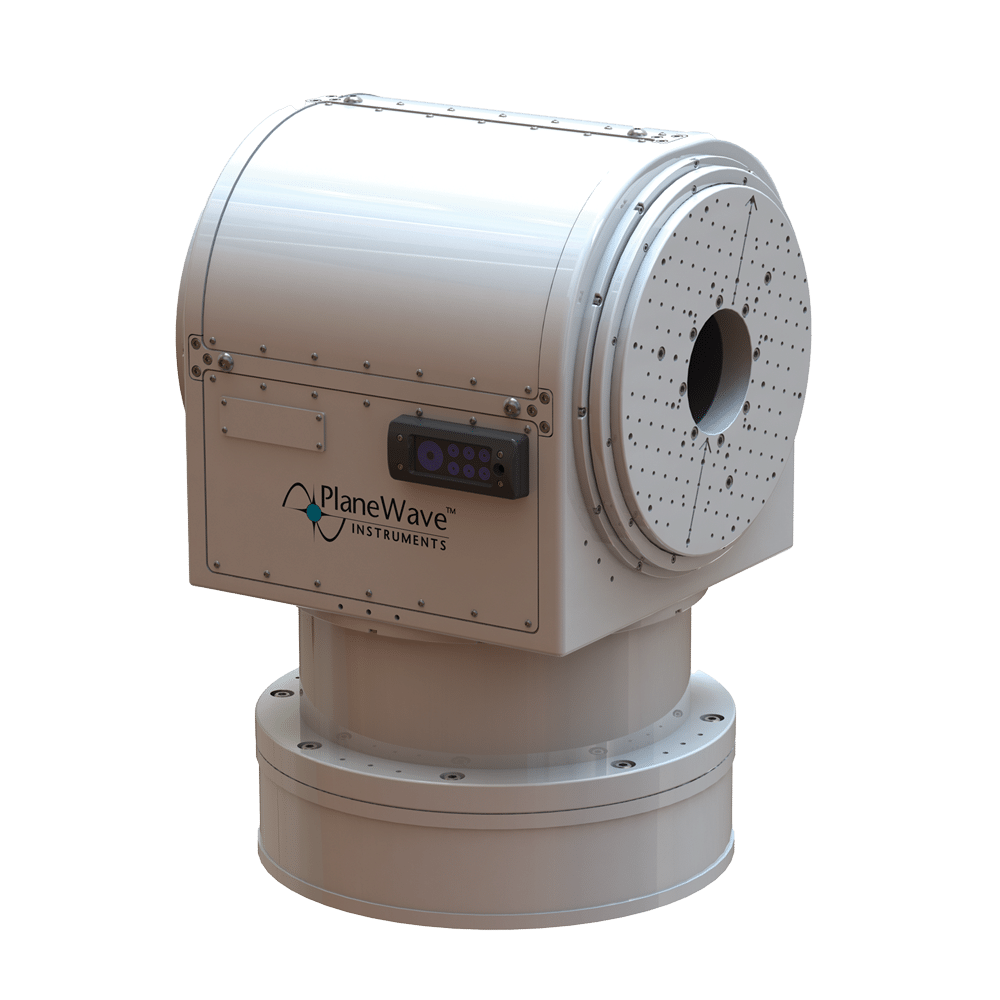

T-600 Direct-Drive Telescope Gimbal

$81,000.00

The PlaneWave T-600 Direct Drive Gimbal is engineered to meet the rigorous demands of advanced astrophotography, complex astronomical research, SSA/SDA, and FSOC applications. Leveraging cutting-edge technology, this gimbal provides a robust, precise, versatile observational platform suitable for demanding environments.

*Price excludes shipping and crating. See our crating and pricing policy for full details.

Key Features Overview

The T-600 Gimbal stands out with its formidable specifications:

- 600 lbs payload capacity

- High-torque, double-stacked direct-drive motors for zero backlash, zero periodic error, and high-speed slewing capabilities up to 100 degrees per second

- High-resolution absolute encoders for ultra-precise positioning

- Enhanced ruggedization with double-layer labyrinth seals on each axis

- Advanced PointXP mount modeling software included

- Configurable for diverse operational goals, including Alt/Az, Alt/Alt, or Equatorial configurations

Core Features of the T-600 GimbalHigh-Torque Direct-Drive MotorsThe T-600 Gimbal has high-torque, double-stacked direct-drive motors, ensuring smooth, fast, and virtually silent operation. This feature is critical for tracking celestial objects with minimal vibration and supreme accuracy, accommodating substantial payloads effectively. High-Resolution Absolute EncodersWith high-resolution absolute encoders on each axis, it offers incredibly precise pointing and tracking capabilities, crucial for capturing sharp, detailed celestial images and conducting rigorous scientific observations. Zero Backlash and Periodic ErrorThe design of the T-600 Gimbal eliminates backlash and periodic error, facilitating consistent and reliable tracking that enhances astrophotography and supports precise applications in research and space surveillance. Advanced Customization OptionsThe T-600 includes optional contact gasket seals for full weatherization and supports limitless Az rotation, making it adaptable for specific research observational requirements across various environments. Rugged and Environment-readyDesigned with rugged environments in mind, the gimbal features electronics enclosed within the mount and weatherproof cable pass-throughs, ensuring durability and reliability in light-to-moderate rain and preventing debris entry. |

Application-Specific AdvantagesAstrophotographyWith its robust load capacity and exceptional slew speeds, it allows astrophotographers to reposition heavy equipment quickly and smoothly, capturing breathtaking images of the cosmos with ease and efficiency. ResearchResearchers will find the gimbal’s precise tracking and advanced software ideal for detailed celestial observations and data collection, particularly in demanding environments where equipment adaptability and operational reliability are paramount. Space Situational Awareness (SSA) and Space Domain Awareness (SDA)Professionals in SSA/SDA will benefit from the T-600 Gimbal’s high-precision tracking and configurable features, which are perfect for monitoring space debris and tracking satellites, ensuring accurate surveillance and data collection in space domain awareness initiatives. |

Experience the

T-600 Direct Drive Gimbal

in action!

Specifications

T-600 Direct-Drive Telescope Gimbal

| Acceleration (Azimuth and Altitude) | Acceleration up to 100°/second² *Depending upon installed payload-induced moment of inertia |

| Velocity | Up to 100 degrees per second *Depending upon acceleration and distance traveled |

| Pointing Accuracy | <5-arcsecond RMS* with PointXP Model *Under stable environmental conditions |

| Pointing Precision | 2 arcseconds at sidereal velocity |

| Open Loop Tracking Accuracy | 0.2 arcseconds RMS over 300 second exposure at siderial rate |

| Open Loop Axis Following Error | <0.15 arcseconds RMS at sidereal rate, <0.3 arcseconds RMS at 1 degree per second* <2 arcseconds RMS at 10 degrees per second* *Dependent on Payload |

| Internal Servo-Loop (Drive to Motor) | 10 kHz cascaded velocity/position controller, PID + Filters |

| Software Command Round-Trip | 5 – 25 msec (depending on application) |

| System Natural Frequency | 20 Hz or greater (for gimbal only) |

| Type | Alt-Azimuth / Equatorial Direct-Drive Mount |

| Weight | 605 lbs |

| Max. Load Capacity | 600 lbs (with payload limited to 100 kg-m² moment per port with center of gravity ≤ 15 inches from mounting surface and an lowest eigenmode frequency of 20 Hz. i.e. dual mounted CDK24 telescopes are compatible) |

| Dimensions | 34” x 20” x 23.5” (H/D/W) |

| Latitude Range | 0 to 90 degrees, Northern and Southern hemispheres |

| Motor Torque (Azimuth and Altitude) | 127 ft-lbs (peak) |

| Azimuth Axis Range of Motion (Optional) | |

| Cable Management | Through-the-mount cabling |

| Coudé Path (Optional) | Limits elevation axis range of motion to 180º |

| Power Requirement | 100 to 240 VAC (50-60 Hz), 20 amp service at 120 VAC, 10 amp service at 240 VAC |

| Operating Temperature Range | -30 C to +50 C |

| Storage Temperature Range | -50 C to +70 C |

| Gimbal Assembly | Fully CNC machined construction (Surface finish treated with UV resistant coating on all exposed metal surfaces) |

| Default Weatherization | 2-Layer non-contact labrynth sealing at each motion-surface to prevent water (light-to-moderate rain) and debris entry. *Optional rubber seals may be added for further ruggedization. |

| Azimuth Bearing | 4-way loaded radial ball bearings |

| Altitude Bearing | 4-way loaded radial ball bearings |

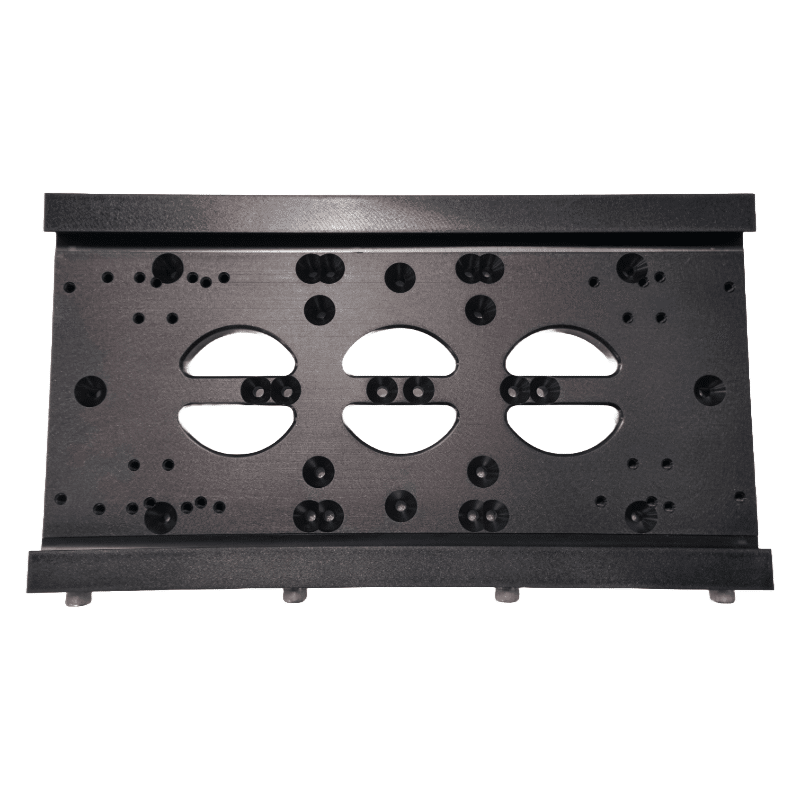

| Instrument Mounting | Breadboard plate on both mounting surfaces (see interface document for complete mounting information) |

| Lifting Points | Present for lifting in “any orientation” |

| Drive Electronics (Azimuth and Altitude) | Elmo Motion Control Systems industrial grade off-the-shelf brushless motor drives |

| Motors (Azimuth and Altitude) | Each axis includes a double stacked direct-drive 3 phase axial-flux torque motor |

| Encoders (Azimuth and Altitude) | 26-bit absolute encoder ring with readhead |

| User Interface | PlaneWave Interface 4 (PWI4) Control Software with integrated PointXP mount modeling software by Dave Rowe. Includes ASCOM driver. |

| Advanced Timing Features (Optional) | Timestamped using GPS Reciever, or PTP/NPT Server <100-microseconds accuracy |

| Included Items | Hardware- Six 1/2-13 x 1 1/4″ socket head cap screws to bolt the mount to the pier or wedge; Six 1/2-13 washers; One extended length shoulder bolt for RA axis to EQ wedge alignment |

| One 16' USB cable - Too connect the mount to the observatory control computer | |

| One 120VAC power cable- to provide power to the mount | |

| Flashdrive - Contains PWI4 software for mount control , instructions for installation, software, and instructions for collimation and spacing the primary to secondary mirror | |

| 3/8 Socket - Used for operating the RA balance leadscrew on the mount | |

| Gamepad - Used for control of the mount tracking speeds for visual observing | |

Recommended Products

| Image | Name | Summary | Price | Buy |

|---|---|---|---|---|

| Portable Rolling Pier | Don’t let bad weather stop you from enjoying your L-Series Mount every clear night. The Portable Rolling Pier lets you move your L-series Mount and telescope to the best spot for stargazing in no time. Just grab the steering T-handle and roll it wherever you want! With the auto-mount modeling feature in our PWI software, your L-Mount will be ready to capture amazing night sky images in minutes. | $10,000.00 | ||

| Telescope Dovetail Saddles | The Keller EZ Saddle (600182) accepts Losmandy D-style dovetail rails such as the CDK12.5, CDK14, and DeltaRho 350. This saddle comes standard with the L-350 mount and can also be attached to the outside arm of any L-series mount for dual-mounted OTA configurations. The PlaneWave Wide Saddle (200919) comes standard with L-500, L-550, and L-600 mounts for securing CDK17, CDK 20, CDK24, and DeltaRho 500 telescopes. | $460.00 | ||

| Piers for L-350 Mounts |

| $2,650.00 – $3,700.00 | ||

| Piers for L-500 and L-600 Mounts |

| $2,650.00 – $3,700.00 |