Optical Design

The CDK Optical Design

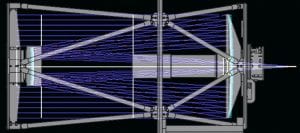

The CDK [Corrected Dall-Kirkham] telescope is based on a new optical design developed by Dave Rowe. The goal of the design is to make an affordable astrographic telescope with a large enough imaging plane to take advantage of the large format CCD cameras of today. Most telescope images degrade as you move off-axis from either coma, off-axis astigmatism, or field curvature. The CDK design suffers from none of these problems. The CDK is coma free, has no off-axis astigmatism, and has a flat field. The design is a simple and elegant solution to the problems posed above. The CDK consists of three components: an ellipsoidal primary mirror, a spherical secondary mirror and a lens group. All these components are optimized to work in concert in order to create superb pinpoint stars across the entire 52 to 100 mm image plane.

The CDK [Corrected Dall-Kirkham] telescope is based on a new optical design developed by Dave Rowe. The goal of the design is to make an affordable astrographic telescope with a large enough imaging plane to take advantage of the large format CCD cameras of today. Most telescope images degrade as you move off-axis from either coma, off-axis astigmatism, or field curvature. The CDK design suffers from none of these problems. The CDK is coma free, has no off-axis astigmatism, and has a flat field. The design is a simple and elegant solution to the problems posed above. The CDK consists of three components: an ellipsoidal primary mirror, a spherical secondary mirror and a lens group. All these components are optimized to work in concert in order to create superb pinpoint stars across the entire 52 to 100 mm image plane.

Optical Performance

Shown are two simulations showing the CDK’s stunning performance. The first is a diffraction simulation and the second is a spot diagram. In both simulations, the small squares are 9×9 microns, about the size of a CCD pixel. In the diffraction simulation, the star images on axis and off-axis are nearly identical. In the spot diagram 21mm off-axis the spot size is an incredible 6 microns RMS diameter. This means stars across a 52 mm image circle are pinpoints as small as the atmospheric seeing will allow.

Shown are two simulations showing the CDK’s stunning performance. The first is a diffraction simulation and the second is a spot diagram. In both simulations, the small squares are 9×9 microns, about the size of a CCD pixel. In the diffraction simulation, the star images on axis and off-axis are nearly identical. In the spot diagram 21mm off-axis the spot size is an incredible 6 microns RMS diameter. This means stars across a 52 mm image circle are pinpoints as small as the atmospheric seeing will allow.

Both of the simulations take into consideration a flat field, which is a more accurate representation of how the optics would perform on a flat CCD camera chip. For visual use, some amount of field curvature would

Comparison: CDK vs. Ritchey Chrétien

The simulations shown compares the optical performance of the CDK design to the Ritchey Chrétien (RC) design. The Ritchey design was popularized as an astroimaging telescope due to its use in many professional observatories. Although very difficult and expensive to manufacture and align, the Ritchey is successful in eliminating many of the problems that plague many other designs, namely off-axis coma. However the Ritchey does nothing to eliminate the damaging effects of off-axis astigmatism and field curvature.

The CDK design tackles the off-axis coma problem by integrating a pair of correcting lenses into a two mirror design. The beauty is that this design also corrects for astigmatism and field curvature. Because the lenses are relatively close to the focal plane (unlike the Schmidt corrector plate found in various Schmidt Cassegrain designs), and because these lenses work together as a doublet, there is no chromatic aberration. The CDK offers a wide aberration-free, flat field of view that allows the user to take full advantage of the very large imaging chip cameras in the market place today.

Having an aberration free telescope design means nothing if the optics cannot be aligned properly. Many Ritchey owners never get to take full advantage of their instrument’s performance because the Ritchey is very difficult to collimate. Aligning the hyperbolic secondary mirror’s optical axis to the optical axis of the primary mirror is critical in the Ritchey design, and the tolerances are unforgiving. The secondary mirror of the CDK design is spherical. It has no optical axis and so the centering tolerance of the CDK secondary mirror is comparatively huge. With the help of some very simple tools, the CDK user will be able to set the secondary spacing, collimate the optics and begin enjoying the full performance potential the instrument has to offer within a few minutes.

The drastic difference in performance between the CDK and the RC is apparent. The biggest component that degrades the off-axis performance of the RC is the defocus due to field curvature. In many diagrams shown by RC manufacturers, the diagrams look better than this because they are showing a curved focal plane. This is fine for visual use because the eye can compensate for some amount of curvature of field. But CCD arrays are flat and so in order to evaluate the performance a spot diagrams and/or diffraction simulations requires a flat field as shown.

Optical Testing and Manufacturing

At PlaneWave Instruments, we take pride in the excellent optical quality of our telescopes. Each optical component of our systems goes through an extensive process of figuring, testing and inspection to guarantee excellent performance from every telescope we produce.

PlaneWave Instruments technicians use a custom optical metrology measurement system to generate a precision surface wavefront map for every mirror at each stage of the manufacturing process. This data is used in one of our state-of-the-art, robotic optics figuring machines to smooth and correct any errors present in the mirror surface. This measurement and figuring process is repeated until each mirror meets the exacting quality required for every PlaneWave telescope.

After final figuring, our mirrors are coated, inspected, mounted in their support cells and the optical quality measurement is repeated to ensure that no surface errors have been introduced during the process. This is a critical step to ensure that the mirror will perform when installed into the completed telescope. Many other manufacturers skip this important test or remove astigmatism and other errors from their measurements. At PlaneWave Instruments, we understand that these errors cannot be ignored and can be detrimental to the quality of the complete telescope, so we do not pass a mirror on final assembly without verifying the complete surface wavefront.

In addition to testing each optical component during the manufacturing process, PlaneWave Instruments tests every one of our telescopes as a complete finished system in one of our modern test bays. This allows us to ensure that each optical system is of the highest quality before it is shipped to a customer. Because our test bays are independently temperature controlled, we can reduce atmospheric fluctuations that typically affect on-sky measurements, allowing for the most precise measurement of the quality of the telescope. This allows our expert technicians to efficiently identify and correct any residual alignment or figure errors in the complete optical system. This final optical test is the ultimate guarantee that our telescopes will yield the excellent performance that our customers have come to expect.